Why Is Anti-Static Veneer Becoming the Preferred Surface Material for Modern Interiors?

2025-10-31

In today’s high-tech, precision-driven environments, the demand for safe, reliable, and aesthetically appealing surface materials has never been higher. Anti-static veneer represents a new generation of engineered surface coverings designed to eliminate electrostatic discharge (ESD) while maintaining the rich, natural beauty of traditional veneers. It combines advanced anti-static technology with high-quality substrates, creating a material that is both functional and visually appealing.

Electrostatic discharge can cause significant damage to sensitive electronic components, attract dust, and even compromise safety in industrial or medical settings. Anti-static veneer is specifically designed to prevent these issues, offering a conductive or dissipative surface that neutralizes static charges immediately. Unlike conventional laminates or decorative veneers, anti-static veneer integrates carbon-based compounds and conductive polymers that ensure consistent performance without sacrificing design flexibility.

Why Is Anti-Static Veneer Important for Modern Environments?

Modern workspaces, hospitals, laboratories, and electronic manufacturing areas demand surface materials that combine safety, hygiene, and durability. Traditional decorative veneers—while visually appealing—often fail to address electrostatic risks. Anti-static veneer bridges that gap by incorporating a controlled electrical resistance value, typically between 10⁶ to 10⁹ ohms, which ensures that static charges dissipate safely into the ground.

Below is a detailed technical specification table that highlights the professional parameters of anti-static veneer:

| Parameter | Specification | Description |

|---|---|---|

| Surface Resistance | 10⁶ – 10⁹ Ω | Ensures safe dissipation of static charges |

| Material Composition | PVC + Conductive Carbon + Resin Layer | Combines conductivity with durability and design flexibility |

| Surface Finish | Matte / Gloss / Textured | Offers multiple aesthetic options |

| Thickness Range | 0.8mm – 2.0mm | Suitable for flooring, furniture, wall cladding |

| Abrasion Resistance | ≥ 6000 cycles | Excellent wear performance for heavy-traffic areas |

| Fire Retardancy | B1 Grade | Complies with interior safety standards |

| Chemical Resistance | Strong resistance to acids, alkalis, and solvents | Ideal for laboratories and hospitals |

| Moisture Resistance | ≤ 1% water absorption | Ensures dimensional stability in humid environments |

| Temperature Tolerance | -20°C to +70°C | Stable in a wide range of environmental conditions |

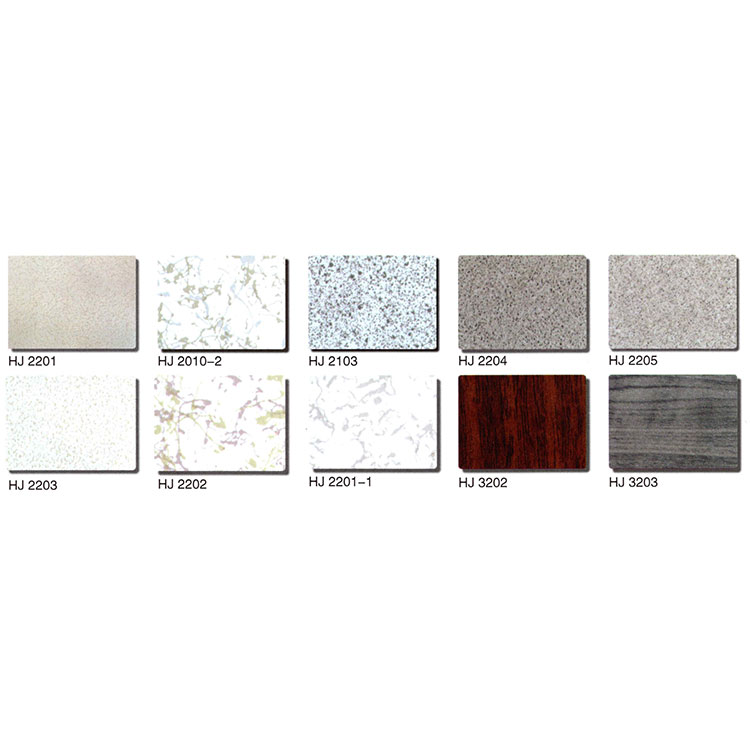

| Color Options | Customizable | Matches various design themes and corporate branding |

By addressing both performance and aesthetic needs, anti-static veneer has become an essential material for environments where static control, hygiene, and durability are critical.

How Does Anti-Static Veneer Work and Where Is It Used?

Anti-static veneer functions by incorporating conductive materials within its surface and backing layers. These materials create a microscopic network that channels static electricity away from the surface, safely dissipating it through grounding systems. This mechanism prevents the accumulation of static charge that could otherwise damage sensitive electronic devices or attract airborne contaminants.

The structure of anti-static veneer typically consists of:

-

Decorative Surface Layer – Provides the desired appearance (wood grain, marble, metallic, or solid color).

-

Conductive Layer – Embedded with carbon black or metallic fillers that enable static dissipation.

-

Base Substrate – Reinforced resin or polymer core ensuring mechanical strength.

-

Protective Coating – Enhances wear resistance, UV protection, and chemical stability.

Applications of Anti-Static Veneer include:

-

Electronics Manufacturing Facilities: Prevents static damage to circuit boards and microchips.

-

Hospitals and Laboratories: Maintains hygienic, dust-free surfaces and prevents contamination.

-

Data Centers: Protects sensitive servers and networking equipment.

-

Clean Rooms: Ensures controlled environments where static and dust are unacceptable.

-

Office Spaces and Control Rooms: Provides safety while maintaining modern interior aesthetics.

In addition to its technical advantages, anti-static veneer offers remarkable design flexibility. It can replicate the appearance of natural wood, stone, or metal surfaces while maintaining its conductive properties. This makes it a preferred choice for architects and designers who seek a balance between functionality and visual appeal.

What Are the Key Advantages of Anti-Static Veneer?

1. Enhanced Safety and Static Control

Anti-static veneer prevents electrostatic buildup, reducing the risk of fire, equipment damage, and system failure. This is especially critical in industries where sensitive components or flammable substances are present.

2. Long-Term Durability

Its high abrasion and chemical resistance make it suitable for high-traffic areas and harsh conditions, ensuring long service life with minimal maintenance.

3. Superior Cleanliness and Hygiene

Unlike porous materials that attract dust and bacteria, anti-static veneer repels contaminants, making it ideal for sterile environments like hospitals and clean rooms.

4. Aesthetic Versatility

With advanced printing and surface coating technologies, anti-static veneer offers an extensive range of finishes—from natural wood grains to modern metallic tones—allowing seamless integration into any design concept.

5. Sustainability and Environmental Responsibility

Modern anti-static veneers are increasingly made with eco-friendly resins and low-VOC adhesives, aligning with global green building standards and certifications.

6. Cost Efficiency

Compared with solid surface materials or conductive flooring, anti-static veneer provides comparable performance at a lower cost, making it a practical choice for large-scale projects.

Common Questions About Anti-Static Veneer

Q1: What makes anti-static veneer different from traditional decorative veneer?

A1: The key difference lies in its ability to dissipate electrostatic charges. Traditional decorative veneers focus purely on appearance, while anti-static veneer incorporates conductive compounds that prevent static buildup. This makes it ideal for environments with electronic devices or precision equipment.

Q2: How long does anti-static veneer maintain its conductivity?

A2: When properly installed and maintained, anti-static veneer can retain its conductive performance for over 10 years. The conductive layer is embedded within the material, ensuring consistent resistance values even after prolonged use, provided the surface is kept clean and free of insulating contaminants like wax or oil.

What Is the Future Trend of Anti-Static Veneer in the Industry?

The demand for anti-static materials is rapidly expanding, driven by the growth of electronics manufacturing, AI data centers, and smart buildings. As industries adopt more sophisticated automation systems, the need for materials that ensure both electrical safety and aesthetic harmony continues to rise.

Future developments in anti-static veneer technology focus on:

-

Nanotechnology Integration: To enhance conductivity precision without affecting design flexibility.

-

Eco-Friendly Formulations: Development of solvent-free, recyclable veneer materials for sustainable construction.

-

Smart Surface Innovations: Integration of self-healing coatings and embedded sensors for monitoring surface performance.

-

Broader Design Applications: Expansion beyond industrial use to luxury offices, hospitals, and high-end residential interiors.

Architects and designers are now prioritizing materials that combine function, beauty, and safety—qualities that define anti-static veneer as a next-generation solution. Its ability to reduce risks, improve efficiency, and complement modern design aesthetics positions it as a leading choice for both commercial and industrial environments.

Conclusion: Why Choose Vinyl Anti-Static Veneer?

Anti-static veneer has transformed from a niche technical product into a mainstream design material that supports the evolving needs of technology-driven spaces. With its blend of safety, durability, and aesthetic appeal, it represents the perfect balance between form and function.

Vinyl stands out as a trusted brand offering high-quality anti-static veneers that meet international standards for performance and design. With years of manufacturing expertise, advanced production technology, and a commitment to innovation, Vinyl provides customized solutions tailored to various industries and interior design requirements.

For professionals seeking reliable and stylish anti-static solutions, Vinyl’s Anti-Static Veneer offers unmatched performance and long-term value.

Contact us today to learn more about our anti-static veneer collections and discover how Vinyl can help elevate your projects with safe, modern, and sustainable surface solutions