How to judge the quality of anti-static floor

In order to avoid the harm caused by static electricity, many computer rooms will install anti-static floor. There are many brands of anti-static floor on the market, so how to judge the quality of anti-static floor?

1. Look at the veneer material

Anti-static floor is roughly divided into three types according to the veneer, and different types have different performance characteristics:

①PVC veneer anti-static floor has a soft texture, comfortable to wear, stable anti-static performance, and weak wear resistance;

②HPL veneer anti-static floor has a hard texture, good wear resistance, Class A fireproof and safe, wear and corrosion resistance, and a long service life;

③Ceramic veneer anti-static floor has a hard texture, mirror glass effect, wear and corrosion resistance, easy maintenance, and a long service life.

Our anti-static floor veneer mainly starts from three aspects: wear resistance, veneer thickness and anti-static performance. If the thickness of the inferior anti-static floor veneer does not meet the standard thickness, the service life of the anti-static floor will be greatly shortened.

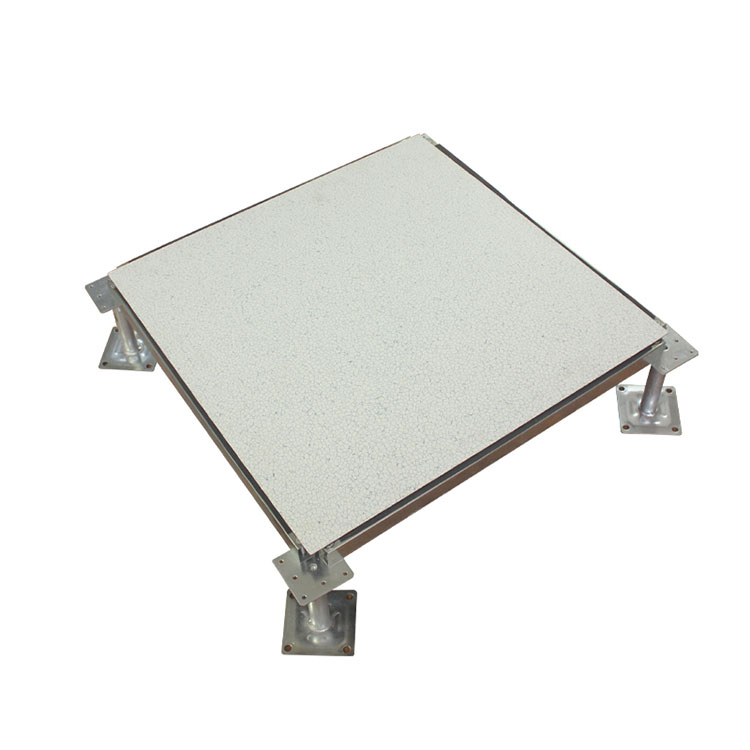

2. Look at the steel shell

The steel shell is mainly its thickness, which will affect the bearing capacity of the anti-static floor. For overhead anti-static floor, load-bearing capacity is particularly important, because we want the anti-static floor not to collapse when placing equipment. Ordinary steel shell is 04/05, and there are different compositions such as thickened 05/06, 06/07, 07/08. The thicker the steel shell, the better the load-bearing capacity, and of course the higher the price.

Poor quality anti-static floor will cut corners on the standard thickness, for example: the thickness of the steel plate is 1.0mm, and it is cut to 0.3, 0.4mm, which greatly reduces the thickness. This thickness does not reach the required strength and is easy to cause the floor to crack

3. Look at the accessories

The anti-static floor is used with bracket beams. The bracket beams are connected to form an overhead structure at the bottom of the floor, and the floor is placed on top. High-quality parts can ensure overall reliability. Too thin wall thickness is easy to cause overall instability, shaking, and warping. In severe cases, it will cause problems such as collapse and rupture

Therefore, our anti-static floor is less affected by external environmental conditions, and will not have obvious expansion and contraction due to excessive or low external environmental temperature.

If you are interested in our products or have any questions, please feel free to contact us and we will reply you within 24 hours.