How Does All Steel Anti-static Access Flooring Prevent Electrostatic Discharge

2025-08-28

Have you ever walked across a room and felt a sudden zap when touching a doorknob? That small shock is a simple example of electrostatic discharge (ESD). Now, imagine that same zap, but multiplied a thousand times, hitting a sensitive server or a medical device. The damage can be immediate and catastrophic, leading to costly downtime and data loss. In my two decades of seeing technology evolve, one constant remains: the critical need to protect sensitive electronics from this invisible threat. This is where a robust All Steel Anti-static Activity Floor comes into play, acting as the first and most important line of defense.

What Exactly Is Electrostatic Discharge and Why Should You Care

Electrostatic discharge is the sudden flow of electricity between two charged objects. It’s not just about personal discomfort. In environments like data centers, server rooms, and laboratories, ESD can silently destroy circuit boards, corrupt data, and cause hardware failures that bring operations to a screeching halt. You might not see it happening, but the effects are real and expensive. I've consulted with countless businesses who learned this lesson the hard way after a preventable ESD event. The question isn't if ESD will occur, but how you are prepared to stop it.

How Does an All Steel Anti-static Activity Floor Work to Neutralize Threat

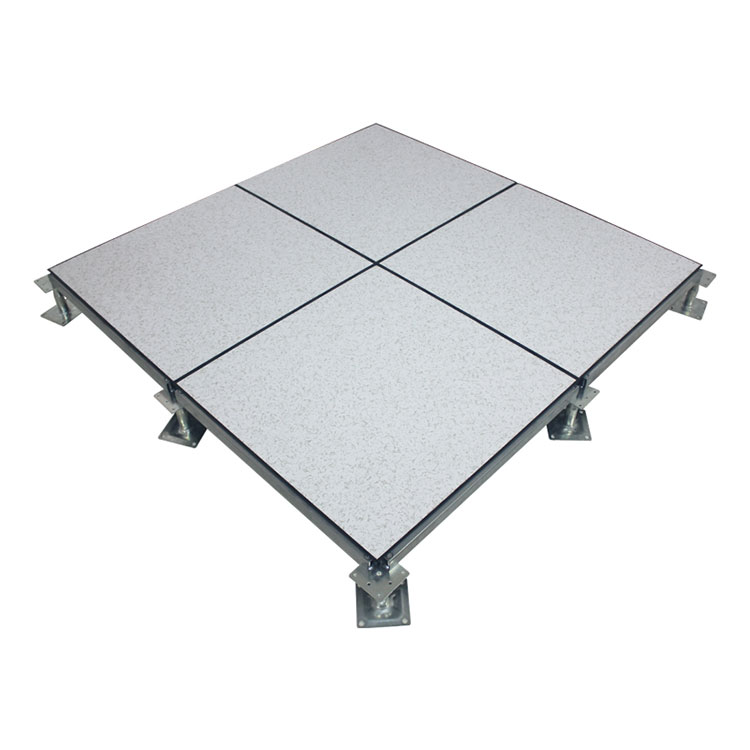

An All Steel Anti-static Activity Floor is a sophisticated system designed to control and dissipate static electricity safely to the ground. It doesn't just insulate; it actively protects. The core mechanism involves a combination of materials and engineering. The steel substrate provides a highly conductive path. A durable, dissipative surface layer, like the high-pressure laminate (HPL) we use in our Huahong brand floors, allows static charges from people and equipment to flow across the surface without building up. These charges are then safely channeled through the conductive pedestals and into the building's grounding system. This continuous path neutralizes the threat before it can reach your valuable equipment.

What Are the Key Performance Parameters of a High-Quality Floor

When investing in an All Steel Anti-static Activity Floor, you must look beyond the surface. The technical specifications are what guarantee true protection. Here are the critical parameters that define a superior floor, based on international standards:

-

System Resistance: This measures the floor's ability to conduct electricity. A perfect balance is needed—too conductive and it becomes a safety hazard; too resistant and it won't dissipate charge.

-

Optimal Range: Between 1.0 x 10^6 and 1.0 x 10^9 ohms (as per IEC 61340-5-1).

-

-

Load Capacity: The floor must support heavy equipment without deforming.

-

Concentrated Load: ≥ 3,200 N (for server racks and large devices).

-

Uniform Load: ≥ 12,000 N/m² (for general equipment and foot traffic).

-

-

Fire Rating: Non-flammability is non-negotiable for safety.

-

Standard: Class A (ASTM E648) or better, ensuring minimal flame spread and smoke generation.

-

-

Surface Hardness and Abrasion Resistance: The top layer must withstand years of heavy use.

-

Standard: ≥ 4,500 rpm (AC4/AC5 grade on the Taber test scale).

-

The following table summarizes these essential specifications for clarity:

| Performance Characteristic | Standard Value & Rating | Importance for ESD Protection |

|---|---|---|

| System Resistance | 10^6 - 10^9 ohms | Ensures controlled dissipation of static charge to ground. |

| Concentrated Load | ≥ 3,200 N | Prevents structural deformation that could break conductive paths. |

| Uniform Load | ≥ 12,000 N/m² | Maintains system integrity under the weight of all equipment. |

| Fire Rating | Class A (ASTM E648) | Protects the facility from fire hazards without compromising the floor. |

| Abrasion Resistance | ≥ 4,500 rpm (AC4/AC5) | Ensures the conductive surface layer remains effective for years. |

Why Choose Huahong's All Steel Anti-static Activity Floor

With so many options on the market, why trust Huahong? From my perspective, it comes down to relentless engineering and proven performance. Our All Steel Anti-static Activity Floor isn't just a product; it's a promise of uninterrupted operation. We use a cold-rolled, fully welded steel shell that is treated with a conductive epoxy finish, ensuring every panel is uniformly protective. The HPL surface is not only highly dissipative but also incredibly durable, resisting scratches, impacts, and stains. We understand that your facility's needs are unique, which is why our floors are designed for easy access to underfloor services without compromising an ounce of protection. When you choose Huahong, you are choosing a partner with a legacy of solving the complex static control problems that keep other managers awake at night.

Is Your Current Flooring Solution Putting Your Assets at Risk

This is the most important question you can ask yourself today. If you're relying on traditional flooring or an inferior system, you are gambling with your most critical assets. The cost of a single ESD-related failure can far exceed the investment in a certified, reliable All Steel Anti-static Activity Floor. Don't wait for a disaster to be your warning.

Protecting your mission-critical environment requires a proven solution. Contact us today to schedule a free consultation with our static control specialists. Let us show you how a Huahong All Steel Anti-static Activity Floor can be tailored to your specific needs, providing peace of mind and unwavering protection for your valuable technology.